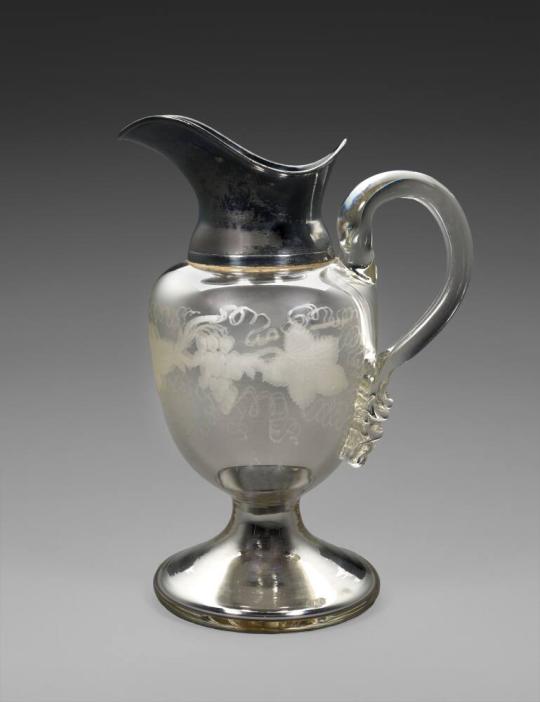

- Pitcher

Explore Further

Silvered glass, first produced in Bohemia (now the Czech Republic) and then England, was popular in the United States from the early 1850s until the late 1870s. This shiny, reflective glassware was normally made for display rather than for use. By the 1840s, manufacturers employed a silver nitrate solution that was applied to the interior of vessels. Silvered glass objects can be single walled, such as a doorknob, but the majority were blown, double-walled objects. The double walls allowed the object to appear silver on the inside and outside. After a piece was blown and annealed, the silvering solution was poured into the small, pontil scar hole of the base. The fluid was swirled around, coating the interior, and the excess drained out. An airtight seal was critical to prevent the silvering from deteriorating. Glass plugs were cemented in, but they were costly and time consuming to make, so most companies used cheap corks that were often covered with paper and wax.

One such example is this silvered glass pitcher attributed to the Boston Silver Glass Company in Cambridge, Massachusetts. John W. Haines, a partner of the glassworks, was granted a patent on April 4, 1865, the date stamped on its silver-plated spout. Wheel engraved with grapevines and tendrils, this classically formed, double-walled pitcher retains its original cork and paper seal. The Boston Silver Glass Company operated from 1857 until 1871. Although they made other types of glass, their production was mostly silvered glass. One company advertisement states, “Silvered & Flint Glass Ware, plain, engraved and embossed, in every variety of style, reflectors, lamps, table ware, ornamental articles, curtain pins, door knobs.”

ProvenanceDorothy-Lee Jones; [The Stradlings, New York]; purchased by MFAH, 2011.

Inscriptions, Signatures and Marks

Cataloguing data may change with further research.

If you have questions about this work of art or the MFAH Online Collection please contact us.